You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thermal finishing plaster

- Thread starter CeeVee

- Start date

Builderboi

Well-Known Member

Vincey

Private Member

What's kinda job is it for ?Anyone know where I can get thermal finishing plaster like aerotherm and the likes?

Need about 5 bags but the only ones I've seen require an "approved installer" lol

27mm therma line plus ?

Vincey

Private Member

Can you skim over it with gypsum finish ?

Builderboi

Well-Known Member

Can you skim over it with gypsum finish ?

Dunno mate not used it yet but very interested after all the info bauwer has posted

Anyone know where I can get thermal finishing plaster like aerotherm and the likes?

Need about 5 bags but the only ones I've seen require an "approved installer" lol

Aerotherm ? Lol

CeeVee

Well-Known Member

Geezer wants an insulating plaster on some solid walls in his house....there's no room to board it as it's on a staircase.What's kinda job is it for ?

27mm therma line plus ?

At that price I think he'll just turn the heating up instead...

Danny

-

@aerotherm @Plasterers1StopShopGeezer wants an insulating plaster on some solid walls in his house....there's no room to board it as it's on a staircase.

At that price I think he'll just turn the heating up instead...

Sent from my SM-N910F using Tapatalk

D

Deleted member 23452

Guest

Aerotherm?  You'd be better off saving the money and sticking cornflake packets to the wall, they have the same insulation value.

You'd be better off saving the money and sticking cornflake packets to the wall, they have the same insulation value.

Compare it to some other materials and you'll see what a load of boll0cks it is.

The thickness of each material needed to give a wall a U value of 0.3 W/m2.K is:

Silica Aerogel ~ 57mm

PIR foam ~ 73mm

EPS foam ~ 118mm

Rock or mineral wool ~ 136mm

AeroTherm = 157mm

Dry timber ~ 292mm

A 1mm layer would make the following % contribution towards the target U value:

Silica Aerogel ~ 1.75%

PIR foam ~ 1.37%

EPS foam ~ 0.85%

Rock or mineral wool ~ 0.73%

AeroTherm = 0.64%

Dry timber ~ 0.34%

So if the customer wants to spend a small fortune to make less than 1% difference to the wall's insulation then crack on. If not, use the phrase 'snake oil' and tell him it's either insulated board inside, EWI, or turn the heating up.

Compare it to some other materials and you'll see what a load of boll0cks it is.

The thickness of each material needed to give a wall a U value of 0.3 W/m2.K is:

Silica Aerogel ~ 57mm

PIR foam ~ 73mm

EPS foam ~ 118mm

Rock or mineral wool ~ 136mm

AeroTherm = 157mm

Dry timber ~ 292mm

A 1mm layer would make the following % contribution towards the target U value:

Silica Aerogel ~ 1.75%

PIR foam ~ 1.37%

EPS foam ~ 0.85%

Rock or mineral wool ~ 0.73%

AeroTherm = 0.64%

Dry timber ~ 0.34%

So if the customer wants to spend a small fortune to make less than 1% difference to the wall's insulation then crack on. If not, use the phrase 'snake oil' and tell him it's either insulated board inside, EWI, or turn the heating up.

Dansouthcoast84

Private Member

to get the uvaules to make a difference you need thickness. do board or spread think be sameGeezer wants an insulating plaster on some solid walls in his house....there's no room to board it as it's on a staircase.

At that price I think he'll just turn the heating up instead...

theclemo

Private Member

Aerotherm?You'd be better off saving the money and sticking cornflake packets to the wall, they have the same insulation value.

Compare it to some other materials and you'll see what a load of boll0cks it is.

The thickness of each material needed to give a wall a U value of 0.3 W/m2.K is:

Silica Aerogel ~ 57mm

PIR foam ~ 73mm

EPS foam ~ 118mm

Rock or mineral wool ~ 136mm

AeroTherm = 157mm

Dry timber ~ 292mm

A 1mm layer would make the following % contribution towards the target U value:

Silica Aerogel ~ 1.75%

PIR foam ~ 1.37%

EPS foam ~ 0.85%

Rock or mineral wool ~ 0.73%

AeroTherm = 0.64%

Dry timber ~ 0.34%

So if the customer wants to spend a small fortune to make less than 1% difference to the wall's insulation then crack on. If not, use the phrase 'snake oil' and tell him it's either insulated board inside, EWI, or turn the heating up.

Aerotherm @Plasterers1StopShop

D

Deleted member 23452

Guest

Another (unpopular) thing to note with this and refurb work in general, is that if you remove more than 25% of the plaster from the inside of any external wall you should notify building control. They will then expect it to come up to current requirements of part L for refurbishment. So it'd need to have a U value of 0.3 or better.

D

Deleted member 23452

Guest

D

Deleted member 29624

Guest

ssshhhhhAnother (unpopular) thing to note with this and refurb work in general, is that if you remove more than 25% of the plaster from the inside of any external wall you should notify building control. They will then expect it to come up to current requirements of part L for refurbishment. So it'd need to have a U value of 0.3 or better.

theclemo

Private Member

D

Deleted member 23452

Guest

Wd40

No. Engine oil for engines, cooking oil for cooking, gun oil for guns ...........

keithuk

Private Member

Just as i was thinking about the training !Aerotherm?You'd be better off saving the money and sticking cornflake packets to the wall, they have the same insulation value.

Compare it to some other materials and you'll see what a load of boll0cks it is.

The thickness of each material needed to give a wall a U value of 0.3 W/m2.K is:

Silica Aerogel ~ 57mm

PIR foam ~ 73mm

EPS foam ~ 118mm

Rock or mineral wool ~ 136mm

AeroTherm = 157mm

Dry timber ~ 292mm

A 1mm layer would make the following % contribution towards the target U value:

Silica Aerogel ~ 1.75%

PIR foam ~ 1.37%

EPS foam ~ 0.85%

Rock or mineral wool ~ 0.73%

AeroTherm = 0.64%

Dry timber ~ 0.34%

So if the customer wants to spend a small fortune to make less than 1% difference to the wall's insulation then crack on. If not, use the phrase 'snake oil' and tell him it's either insulated board inside, EWI, or turn the heating up.

D

Deleted member 23452

Guest

Just as i was thinking about the training !

Your pants are on fire!

Vincey

Private Member

I knew this and it changes again as we close in on the 2020 emission targetAnother (unpopular) thing to note with this and refurb work in general, is that if you remove more than 25% of the plaster from the inside of any external wall you should notify building control. They will then expect it to come up to current requirements of part L for refurbishment. So it'd need to have a U value of 0.3 or better.

Plasterers1StopShop

Well-Known Member

Anyone know where I can get thermal finishing plaster like aerotherm and the likes?

Need about 5 bags but the only ones I've seen require an "approved installer" lol

Give me a call tomorrow mate, can give you a price on bauwer or Aero-therm

Bauwer

Well-Known Member

Anyone know where I can get thermal finishing plaster like aerotherm and the likes?

Need about 5 bags but the only ones I've seen require an "approved installer" lol

As advised above, Bauwer material is available from our partners @Plasterers1StopShop. No approved installer required, as application process is consistent with traditional plastering and rendering.

Bauwer

Well-Known Member

Can you skim over it with gypsum finish ?

Yes, you can. Bauwer Light + Bauwer Finish, primer and skimming with gysum plaster.

If you would use airless putty plasters such as Besisser BAGARG primer is not required.

Bauwer

Well-Known Member

Aerotherm?You'd be better off saving the money and sticking cornflake packets to the wall, they have the same insulation value.

Compare it to some other materials and you'll see what a load of boll0cks it is.

The thickness of each material needed to give a wall a U value of 0.3 W/m2.K is:

Silica Aerogel ~ 57mm

PIR foam ~ 73mm

EPS foam ~ 118mm

Rock or mineral wool ~ 136mm

AeroTherm = 157mm

Dry timber ~ 292mm

A 1mm layer would make the following % contribution towards the target U value:

Silica Aerogel ~ 1.75%

PIR foam ~ 1.37%

EPS foam ~ 0.85%

Rock or mineral wool ~ 0.73%

AeroTherm = 0.64%

Dry timber ~ 0.34%

So if the customer wants to spend a small fortune to make less than 1% difference to the wall's insulation then crack on. If not, use the phrase 'snake oil' and tell him it's either insulated board inside, EWI, or turn the heating up.

Thanks for the detailed comments, very useful information indeed.

I added few comments which are applicable mainly for older buildings with solid stone or brick walls.

"The thickness of each material needed to give a wall a U value of 0.3 W/m2.K "

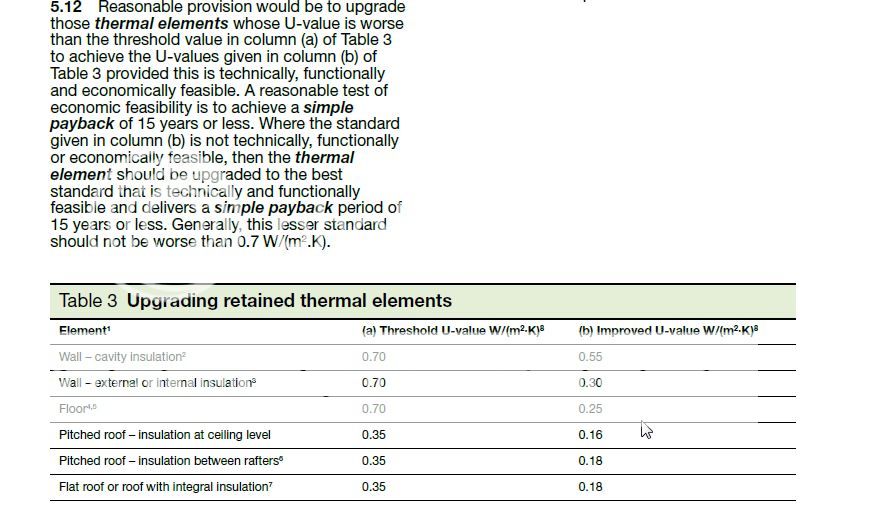

That's a correct requirement if as built U value is 0.7 or better, could you please see extract from the building regs as well as the link to the regs (page 18):

https://www.gov.uk/government/uploa...BR__PDF__AD_L1B_2013_with_2016_amendments.pdf

Typical solid wall as built U value would be about 2, so improvement to 0.7 would mean about 3 times improvement and corresponding reduction in heating bills and reduction of damp. Nothing wrong for older building to achieve U value of 0.7+ in my view.

Over years building method evolved with reduction of as built U value. The interesting fact is that requirement for the cavity wall insulation is U value of only 0.55

It can not be that requirement for the less advanced solid wall is tougher vs more advanced wall with a cavity, does not make sense, does it?

We came across several cases when insulated plasterboard or EPS was used in permeable cottage (to achieve U value 0.3) which resulted in serious damp issues and EPS, insulated plasterboard was removed; so the key is really vapour permeability of the insulation materials in older buildings.

From the list of insulation options above, only "Rock or mineral wool" provides high level of vapour permeability and fit for used in the permeable older buildings, cottages.

I also discussed this issue with few architects at the recent Build Show at NEC Birmingham last week, and their position re cottages U value requirement was either exempt from 0.3 all together or 0.7 being reasonable and sufficient U value to meet building regs (payback section).

I agree with you comments re 1mm of insulation; generally speaking only 1mm of vacuum would deliver a decent contribution toward U value.

Bauwer

Well-Known Member

Another (unpopular) thing to note with this and refurb work in general, is that if you remove more than 25% of the plaster from the inside of any external wall you should notify building control. They will then expect it to come up to current requirements of part L for refurbishment. So it'd need to have a U value of 0.3 or better.

In my view this statement is not correct for cavity wall insulation, eg U value of 0.55 required.

Also as I mentioned above, the requirement of 0.3 is typically not applied to solid stone walls buildings as built U value is much worse vs threshold of 0.7

Otherwise if as built U value is below 0.7 yes 0.3 is expected to be achieved

Bauwer

Well-Known Member

I knew this and it changes again as we close in on the 2020 emission target

We could put any target we want...but the challenge is always to meet it...

At the moment about 7 million of homes in the UK have solid walls and are those walls are NOT insulated.

Assuming 4 person per house, about 30% of the UK's population lives with U value of their walls of about 2.

That would mean large heating bills and damp in some instances as well.

My view is that the interpretation of current requirement as well as lack of funding and budget permeable insulation solutions are potentially responsible for 6 to 7 million of older houses not being insulated.

Basically house owners would chose between 1) spending money for heating vs 2) installing insulation. If option 1) works out cheaper with the simple pay back for the option 2) being 20+ years than the choice is obvious.

Bauwer

Well-Known Member

OK so thermal plaster is useless.

What about the space blanket stuff then boards mechanically fixed to the wall over it?

I disagree, based on the number of older buildings we insulated and the positive feedbacks we receive from our customers. As I said earlier, U value reduction from 2 to 0.7 is achieving a measurable improvement in thermal performance as well as living comfort.

jamesthefirst

Private Member

Yes, you can. Bauwer Light + Bauwer Finish, primer and skimming with gysum plaster.

If you would use airless putty plasters such as Besisser BAGARG primer is not required.

Is the primer lime based and does it contain a grit for key?

Dr.B

Active Member

So if I stud out a wall in front of an old stone wall (as mentioned in another thread) it would be better to use rockwool rather than a celotex type board?Thanks for the detailed comments, very useful information indeed.

I added few comments which are applicable mainly for older buildings with solid stone or brick walls.

"The thickness of each material needed to give a wall a U value of 0.3 W/m2.K "

That's a correct requirement if as built U value is 0.7 or better, could you please see extract from the building regs as well as the link to the regs (page 18):

https://www.gov.uk/government/uploa...BR__PDF__AD_L1B_2013_with_2016_amendments.pdf

Typical solid wall as built U value would be about 2, so improvement to 0.7 would mean about 3 times improvement and corresponding reduction in heating bills and reduction of damp. Nothing wrong for older building to achieve U value of 0.7+ in my view.

Over years building method evolved with reduction of as built U value. The interesting fact is that requirement for the cavity wall insulation is U value of only 0.55

It can not be that requirement for the less advanced solid wall is tougher vs more advanced wall with a cavity, does not make sense, does it?

We came across several cases when insulated plasterboard or EPS was used in permeable cottage (to achieve U value 0.3) which resulted in serious damp issues and EPS, insulated plasterboard was removed; so the key is really vapour permeability of the insulation materials in older buildings.

From the list of insulation options above, only "Rock or mineral wool" provides high level of vapour permeability and fit for used in the permeable older buildings, cottages.

I also discussed this issue with few architects at the recent Build Show at NEC Birmingham last week, and their position re cottages U value requirement was either exempt from 0.3 all together or 0.7 being reasonable and sufficient U value to meet building regs (payback section).

I agree with you comments re 1mm of insulation; generally speaking only 1mm of vacuum would deliver a decent contribution toward U value.

Vincey

Private Member

Thanks Alex,We could put any target we want...but the challenge is always to meet it...

At the moment about 7 million of homes in the UK have solid walls and are those walls are NOT insulated.

Assuming 4 person per house, about 30% of the UK's population lives with U value of their walls of about 2.

That would mean large heating bills and damp in some instances as well.

My view is that the interpretation of current requirement as well as lack of funding and budget permeable insulation solutions are potentially responsible for 6 to 7 million of older houses not being insulated.

Basically house owners would chose between 1) spending money for heating vs 2) installing insulation. If option 1) works out cheaper with the simple pay back for the option 2) being 20+ years than the choice is obvious.

I passed the sample bags onto pft northern as I hadn't had time to use them and didn't want to waste them they had spraying bays and thought their experience and opinion of product would carry more clout than mine

Last edited by a moderator: