Hi All,

First time poster.

I am trying to understand my building control document and the kind of extension that i am having, I gave my architects far too much control and I am at a position now where they have been paid and not really returning my calls.

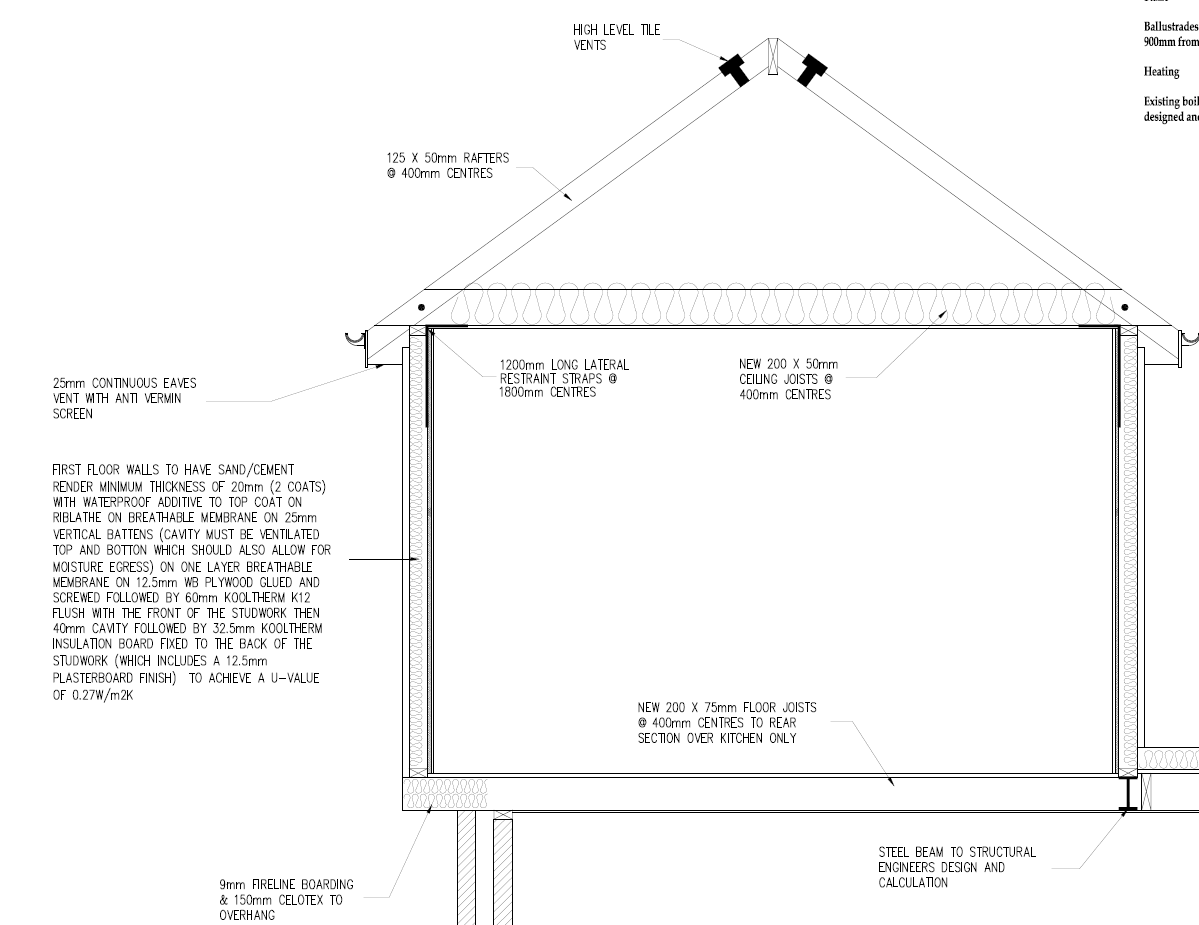

Please see the picture below in terms of the specification of the external walls, its a side extension, and its such that it overhangs, as in not sitting on the existing downstairs blockwork.

I need to understand from a lay mans term the composition of the walls, when looking from outside to inside.

What I usually see is one skin of block work, void for insulation and then another skin of block work.

In one of my notes with the architect, he said Stud work + EML + Sand/Cement render

First time poster.

I am trying to understand my building control document and the kind of extension that i am having, I gave my architects far too much control and I am at a position now where they have been paid and not really returning my calls.

Please see the picture below in terms of the specification of the external walls, its a side extension, and its such that it overhangs, as in not sitting on the existing downstairs blockwork.

I need to understand from a lay mans term the composition of the walls, when looking from outside to inside.

What I usually see is one skin of block work, void for insulation and then another skin of block work.

In one of my notes with the architect, he said Stud work + EML + Sand/Cement render

Last edited: