I posted a while back asking is my builders renderers had done a good job on my house.... long story short, they haven’t. It’s awful. So after waiting months my Builder has finally lined someone up the week after next. I have a couple of questions though if someone can help?

1) The guy is saying I should have a silicon coat over the whole thing. I have paid for monocouche (monoblanco) scratched back to a fine finish I must have at least 15mm of this on already in waves all over the house... he plans to just go over with silicon coat? Is this the same thing and will it give the same finish (that stone /crator look) ? If you recommend this is there a good brand?

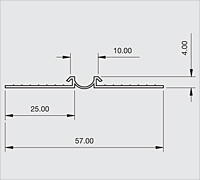

2) he also mentioned putting in an extension bead so he could do the side in 2 parts.... I have never heard of this or seen it but apparently “you won’t even notice” can you confirm this is the case? I don’t want a random stripe down side of house.

3) is this weather (it’ll be starting 28th November) suitable to apply external render??

Thank you, I’m desperate for advice.

1) The guy is saying I should have a silicon coat over the whole thing. I have paid for monocouche (monoblanco) scratched back to a fine finish I must have at least 15mm of this on already in waves all over the house... he plans to just go over with silicon coat? Is this the same thing and will it give the same finish (that stone /crator look) ? If you recommend this is there a good brand?

2) he also mentioned putting in an extension bead so he could do the side in 2 parts.... I have never heard of this or seen it but apparently “you won’t even notice” can you confirm this is the case? I don’t want a random stripe down side of house.

3) is this weather (it’ll be starting 28th November) suitable to apply external render??

Thank you, I’m desperate for advice.