Plasterers1StopShop

Well-Known Member

Wilhelm Kächele GmbH have been developing and producing Rotors and Stators for more than half a century - Successfully!

At PFT Central we are pleased to be stocking a range of the EVEN WALL Stators and Rotors for use with various machines such as; PFT, Utiform, M-tec, EZE and many more.

Kächele are a well known German manufacturer with a fantastic reputation within the marketplace and a huge reputation in Germany

Below is a video illustration link of a Rotor and Stator working for your knowledge

The manufacturers of plaster machines have been waiting for this new geometric design.

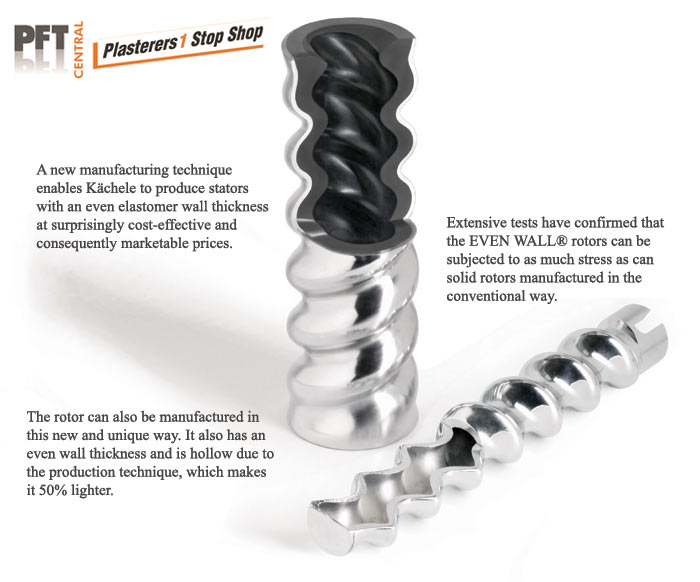

Thanks to this innovative manufacturing method, they now have the chance to use the new rotors and stators in numerous applications for the first time ever. This is why the use of the EVEN WALL® stator in plaster pumps has caught on so quickly. The new stators can be used in almost all machines without any restrictions. Kächele offers a complete pump set for plastering machines.

This consists of optimally co-ordinated precision rotors and stators with an even wall thickness. The stators are maintenance- free and are adapted individually to meet requirements, according to their specific use. Larger delivery heights and even processing of the material as a result of the evenly-shaped delivery flow are decisive advantages, particularly in the construction business.

Here are some advantages of using the EVENWALL range from KÄCHELE:

Cost savings

Lighter in weight

Less Vibration

Easier Handling

Longer service Life

Higher Pressure

One advantage of the even elastomer wall thickness is the generally low degree of heat generation and the considerable improvement in heat dissipation. The elastomer is not nearly as heavily stressed in this version as it is in cylindrical stators.

Wear on the stator is reduced considerably, which means that its service life is significantly extended.

Another important advantage lies in the higher pressure build-up and the associated higher delivery height.

Higher temperatures, an abrasive delivery medium, different chemical and physical compositions of the plaster mixture - all this can be handled better with the new stators.

Without changing the system design, a higher and more constant pump pressure can be generated if an EVEN WALL® stator is employed. This means that the same pumping job can be carried out with a shorter and considerably more compact pump.

Alternatively, the same construction length, delivery pressure and delivery volume can be maintained while the drive power is reduced. This certainly makes itself felt in the operating costs.

The output of existing eccentric screw pumps can be raised to previously unknown levels with this Kächele innovation.

For more information and prices on the Kächele range of Rotors and Stators, please visit: Link Removed

At PFT Central we are pleased to be stocking a range of the EVEN WALL Stators and Rotors for use with various machines such as; PFT, Utiform, M-tec, EZE and many more.

Kächele are a well known German manufacturer with a fantastic reputation within the marketplace and a huge reputation in Germany

Below is a video illustration link of a Rotor and Stator working for your knowledge

The manufacturers of plaster machines have been waiting for this new geometric design.

Thanks to this innovative manufacturing method, they now have the chance to use the new rotors and stators in numerous applications for the first time ever. This is why the use of the EVEN WALL® stator in plaster pumps has caught on so quickly. The new stators can be used in almost all machines without any restrictions. Kächele offers a complete pump set for plastering machines.

This consists of optimally co-ordinated precision rotors and stators with an even wall thickness. The stators are maintenance- free and are adapted individually to meet requirements, according to their specific use. Larger delivery heights and even processing of the material as a result of the evenly-shaped delivery flow are decisive advantages, particularly in the construction business.

Here are some advantages of using the EVENWALL range from KÄCHELE:

Cost savings

Lighter in weight

Less Vibration

Easier Handling

Longer service Life

Higher Pressure

One advantage of the even elastomer wall thickness is the generally low degree of heat generation and the considerable improvement in heat dissipation. The elastomer is not nearly as heavily stressed in this version as it is in cylindrical stators.

Wear on the stator is reduced considerably, which means that its service life is significantly extended.

Another important advantage lies in the higher pressure build-up and the associated higher delivery height.

Higher temperatures, an abrasive delivery medium, different chemical and physical compositions of the plaster mixture - all this can be handled better with the new stators.

Without changing the system design, a higher and more constant pump pressure can be generated if an EVEN WALL® stator is employed. This means that the same pumping job can be carried out with a shorter and considerably more compact pump.

Alternatively, the same construction length, delivery pressure and delivery volume can be maintained while the drive power is reduced. This certainly makes itself felt in the operating costs.

The output of existing eccentric screw pumps can be raised to previously unknown levels with this Kächele innovation.

For more information and prices on the Kächele range of Rotors and Stators, please visit: Link Removed