Yeah. I got a magic mitre block

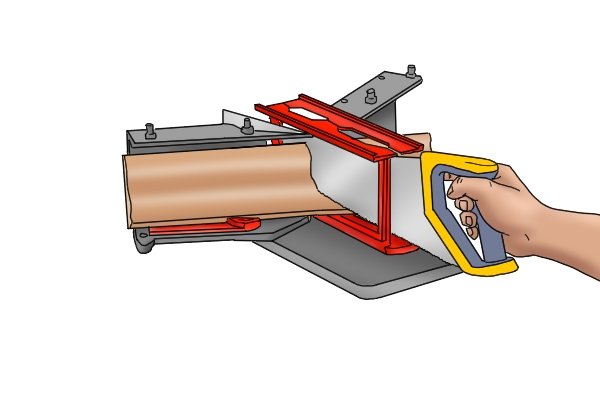

How to use a magic mitre box Shop for Mitre Boxes and Mitre Blocks A magic mitre box is a tool that enables you to match the mitred angle of your skirting or coving to the exact angle of the wall whether that be an internal or external corner. The magic mitre box is a […]

www.wonkeedonkeetools.co.uk

Got the wondertex tool to.

And several I've made from wood the old fashioned type. That one I linked to from B&Q is the strange. Upside down to me but correct way to fit. Go have a look. Odd as hell. You cut from the back of cove to the front.

I used to have a lorry turn at home with 50+ boxes every 3 months. I put 100s of boxes up over the years but it's died off? Put about 5 boxes up this year. Crazy..