You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First attempt at bench running elliptical moulding

- Thread starter Cisco

- Start date

That looks really smart mate, are you self learning, or at college?

Thanks for the comments!

Basically self taught. No college or training ,went to work when I was young after leaving school. Been installing interior stone for the past 3 decades so I have experience in figuring s**t out and have been on jobs were guys were installing fibrous plaster and running in situ, thought I would give it a go.

Cheers

A few progression shots. Finished moulding, keystone and mold, and my little helper

Cheers

Cheers

Attachments

mikeadams1985

Private Member

looks good fella,

but defiantly the long way round,

ellipse can be run quickly, easily and to a perfect ellipse using a trammel.

but defiantly the long way round,

ellipse can be run quickly, easily and to a perfect ellipse using a trammel.

looks good fella,

but defiantly the long way round,

ellipse can be run quickly, easily and to a perfect ellipse using a trammel.

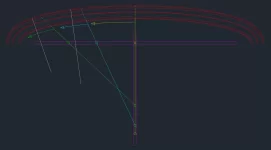

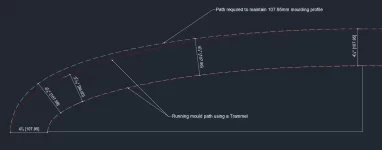

Unfortunately a trammel will not work for this application, I can mark a perfect ellipse with the trammel but I could not use it to run moulding as the major and minor axis have an extreme offset. The major axis is over 180cm and the minor axis is about 19cm. Because the trammel uses pivot points sliding through a preset tracks and not true radius running the knife noticeably would drag through the run skewed once it is off the major and minor axis center points. I attached a cad screenshot to visually explain it, not sure if I am explaining it good enough. In the screenshot you can see the three colored points the knife would run using a trammel. The yellow indicates major axis center pint where the moulding is 107.95mm wide, at the cyan colored line point the knife is running skewed and the moulding is now @ about 101.6mm, at the green colored line point the moulding is now @ about 92mm, as you continue through the run the knife would correct itself When parallel to the major axis. The white lines are the radius angles the knife should be at.

Cheers

Attachments

Last edited:

Unfortunately a trammel will not work for this application, I can mark a perfect ellipse with the trammel but I could not use it to run moulding as the major and minor axis have an extreme offset. The major axis is over 180cm and the minor axis is about 19cm. Because the trammel uses pivot points sliding through a preset tracks and not true radius running the knife noticeably would drag through the run skewed once it is off the major and minor axis center points. I attached a cad screenshot to visually explain it, not sure if I am explaining it good enough. In the screenshot you can see the three colored points the knife would run using a trammel. The yellow indicates major axis center pint where the moulding is 107.95mm wide, at the cyan colored line point the knife is running skewed and the moulding is now @ about 101.6mm, at the green colored line point the moulding is now @ about 92mm, as you continue through the run the knife would correct itself When parallel to the major axis. The white lines are the radius angles the knife should be at.

Cheers

Well foook me thats me confused sounds like NASA putting a man on the moon to me!!!

Danny

-

Well foook me thats me confused sounds like NASA putting a man on the moon to me!!!

yup with you on that

Danny

-

Sorry guys, it wasn't my intent to confuse, just wanted to point out some of the limitations of using a trammel with an oblong ellipse. I try it again with a less confusing drawing.

Cheers

Hahaha I think it is a case of not having any idea about it at all

mikeadams1985

Private Member

cisco, i get ya, it becomes off square so to speak and the more off square the narrower the mould gets.

had that before with a huge mould we had to run but it was a random shape so was a c**t to run without going offsquare

had that before with a huge mould we had to run but it was a random shape so was a c**t to run without going offsquare

Vincenzo dupris

Active Member

Good jobThanks to the info on this site and a few othersI made my first attempt @ bench running some elliptical moldings.

Cheers

Vincenzo dupris

Active Member

I run this curve on a glass tableGood job

Attachments

Sorry for the two year wait. Some install photos.

Cheers

Cheers

Attachments

tapit

Well-Known Member

two years but worth the waitSorry for the two year wait. Some install photos.

Cheers

kebab king

Private Member

Total respect, nice job.

Gavine The First

Well-Known Member

Good work mate.

Second and smaller archway DONE!!!

Cheers

Cheers

Attachments

smoother09

Well-Known Member

That's tasty bud!Sorry for the two year wait. Some install photos.

Cheers

Danny

-

Second and smaller archway DONE!!!

Cheers

Looks ace