kernowspread

Member

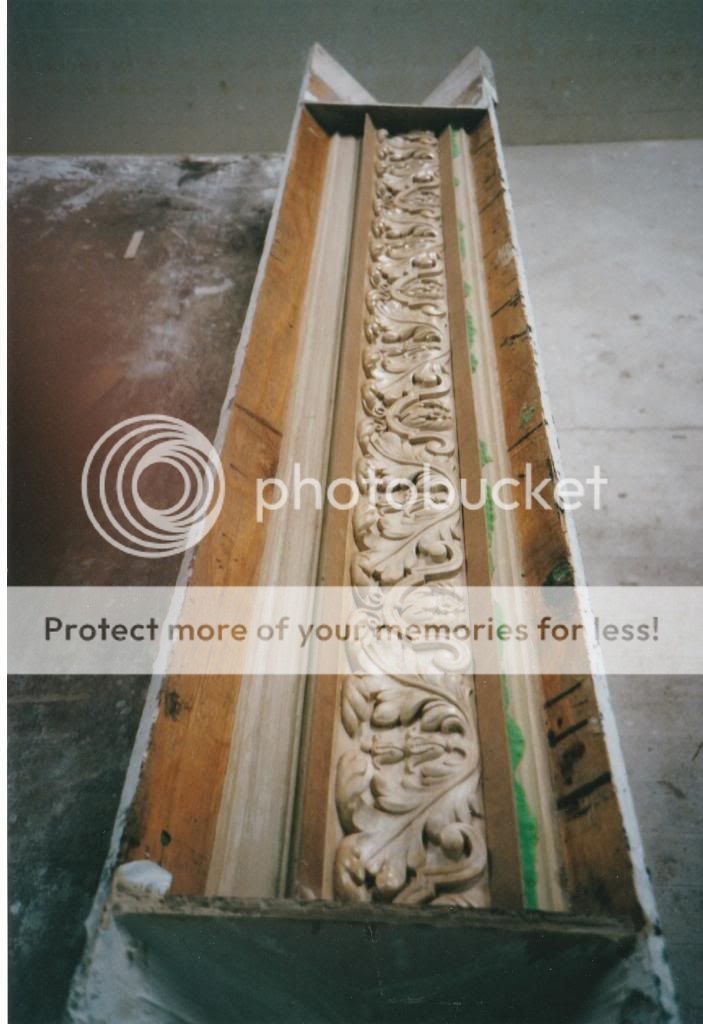

Nearly finished model and trying to get my head round best/most economical way to make a mould.

Nearly finished model and trying to get my head round best/most economical way to make a mould.thinking silicon insert for the enrichment in grp mould rather than full rubber. Anyone got any advice/do's /donts on best way? is thixo applied best way or shuttered and poured?

Any advice would be great, hard when your in workshop on your own with no one to talk stuff through with!

cheers