You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thermal finishing plaster

- Thread starter CeeVee

- Start date

Bauwer

Well-Known Member

Is the primer lime based and does it contain a grit for key?

I would suggest using a primer which does not inhibit water vapour diffusion through the substrate, for example Baumit DG27 available from Mike Wye, https://www.mikewye.co.uk/product/baumit-dg27

Once it dries, yes, it leaves a gritty texture. The primer is required to segregate the layer of Bauwer Finish and gypsum plaster.

Bauwer

Well-Known Member

So if I stud out a wall in front of an old stone wall (as mentioned in another thread) it would be better to use rockwool rather than a celotex type board?

Introduction of impermeable materials (Celotex, EPS, closed cell and extruded plastic insulation, etc) to permeable older buildings can seriously exacerbate existing damp problems and or create new ones.

Clearly, if the walls are already damp before installing insulation these effects will be exacerbated. Under these circumstances it is particularly important to allow walls to ‘breathe’ in order to dry to the outside as effectively as possible. Drying to the inside (external wall insulation with impermeable Celotex, EPS, blocking vapour movement) is significantly less effective, and may be unpleasant for users of the building.

The key is to use permeable materials in permeable older buildings, for example Rocksilk EWI slab, Rockwool,

Bauwer, wood fibre panels, other permeable materials

Bauwer

Well-Known Member

Thanks Alex,

I passed the sample bags onto pft northern as I hadn't had time to use them and didn't want to waste them they had spraying bays and thought their experience and opinion of product would carry more clout than mine

Thank you for this. It would be great if they could share PFT recommendation on Bauwer application, for example helical mixer for insulating plasters need to be used on PFT G4, G5 machines. It is different from a standard mixer.

D

Deleted member 23452

Guest

Thanks for the detailed comments, very useful information indeed.

I added few comments which are applicable mainly for older buildings with solid stone or brick walls.

"The thickness of each material needed to give a wall a U value of 0.3 W/m2.K "

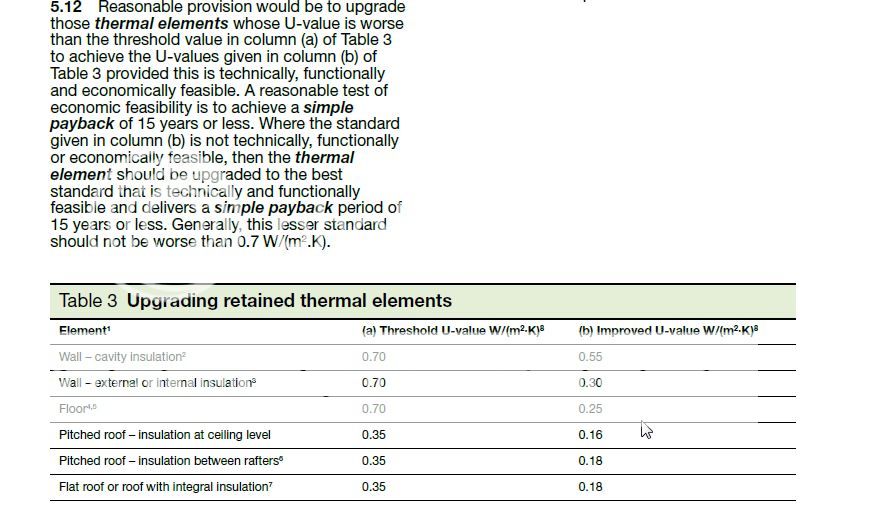

That's a correct requirement if as built U value is 0.7 or better, could you please see extract from the building regs as well as the link to the regs (page 18):

Link Removed

Typical solid wall as built U value would be about 2, so improvement to 0.7 would mean about 3 times improvement and corresponding reduction in heating bills and reduction of damp. Nothing wrong for older building to achieve U value of 0.7+ in my view.

Over years building method evolved with reduction of as built U value. The interesting fact is that requirement for the cavity wall insulation is U value of only 0.55

It can not be that requirement for the less advanced solid wall is tougher vs more advanced wall with a cavity, does not make sense, does it?

We came across several cases when insulated plasterboard or EPS was used in permeable cottage (to achieve U value 0.3) which resulted in serious damp issues and EPS, insulated plasterboard was removed; so the key is really vapour permeability of the insulation materials in older buildings.

From the list of insulation options above, only "Rock or mineral wool" provides high level of vapour permeability and fit for used in the permeable older buildings, cottages.

I also discussed this issue with few architects at the recent Build Show at NEC Birmingham last week, and their position re cottages U value requirement was either exempt from 0.3 all together or 0.7 being reasonable and sufficient U value to meet building regs (payback section).

I agree with you comments re 1mm of insulation; generally speaking only 1mm of vacuum would deliver a decent contribution toward U value.

Thanks for the detailed response. I think the only thing I'd add is that no provision is made in the target U values for a permeable wall or insulation layer.

By this I mean that if the insulation is breathable, and the wall is damp then the insulation properties of the wall and it's coverings are massively reduced. Any moisture in them will form a very efficient cold bridge over the whole area affected by the moisture.

The best solution in those instances is an impermeable inner layer (insulated board etc) separated from the mass of the wall by a vented cavity.

If a material such as rockwool is used in contact with a damp wall it will not provide satisfactory according to the requirements of either the customer or the regulations.

All of which clearly illustrates that there is no single solution to insulating an old building, and also that the building regulation requirements are flawed and sometimes contradictory when it comes to older buildings.

D

Deleted member 23452

Guest

This is like Mike Tyson v Evander Hollyfield

No ear biting or fighting, just a good technical debate.

There's a lot more to construction than is apparent at first glance, and it's always good to get things discussed as we can all learn from it.

Vincey

Private Member

Agree, that's why I loving this thread..No ear biting or fighting, just a good technical debate.

There's a lot more to construction than is apparent at first glance, and it's always good to get things discussed as we can all learn from it.

Ding ding,

Hope it goes 12 rounds

Pug

Well-Known Member

No ear biting or fighting, just a good technical debate.

There's a lot more to construction than is apparent at first glance, and it's always good to get things discussed as we can all learn from it.

Seems to me that in this instance though, while there are many solutions, all of them have some sort of drawback...

D

Deleted member 23452

Guest

Seems to me that in this instance though, while there are many solutions, all of them have some sort of drawback...

Absolutely, they are all compromises.

Trying to make an old building work as it should with modern heating systems, wall finishes, insulation and the amount of internal moisture generated is never going to be completely successful. The closer to getting it to work you get the more expensive it is until you reach a point where the most economically viable solution is to flatten it and start again.

D

Deleted member 23452

Guest

On seriously note though @Bauwer got good product imo, also worth throwing in the debate is I seen a post off a dude yesterday saying with the cost of metal and wood rising maybe float and set is coming full circle, can't stop thinking it will when think about it like that

I've no idea if @Bauwer 's gear is good or not, but the lack of bullsh1t claims and pseudo science in their information is a good sign IMHO.

I think the pre-finished wall panels may start to move through from bathrooms to the rest of the house. They're already gaining popularity for kitchens.

Pug

Well-Known Member

Don't let your BG overlords hear you talking like that Pete!On seriously note though @Bauwer got good product imo, also worth throwing in the debate is I seen a post off a dude yesterday saying with the cost of metal and wood rising maybe float and set is coming full circle, can't stop thinking it will when think about it like that

Vincey

Private Member

It's true though,to be able to fire the gear through machine,float,key and then skim plus the insulation value added and benefits of the product ,cant lie it sounds greatDon't let your BG overlords hear you talking like that Pete!

theclemo

Private Member

U can't float the Bauwer LightIt's true though,to be able to fire the gear through machine,float,key and then skim plus the insulation value added and benefits of the product ,cant lie it sounds great

Vincey

Private Member

Yeah light is the finish coat ,have you used any of the products yet ?U can't float the Bauwer Light

theclemo

Private Member

Yes I used the free samples. I have a job to do external job with it not sure when the job is ready though. But your welcome to do it with meYeah light is the finish coat ,have you used any of the products yet ?

Vincey

Private Member

Tbh I want to do a whole room with the base coat and then finish coat see how it all comes up,see if it comes up good enough finish for customer to just paint,what I don't get is how thick it would need to be to equal (lets say for example) a 27mm or 50mm thermaline plus board ( I know all info is in website somewhere ) but in simple language,how thick?Yes I used the free samples. I have a job to do external job with it not sure when the job is ready though. But your welcome to do it with me

Same with the outside would like to do/ see a big area done tbh I can't judge anything with out doing it myself

Vincey

Private Member

What you using today?Yes I used the free samples. I have a job to do external job with it not sure when the job is ready though. But your welcome to do it with me

theclemo

Private Member

My cockWhat you using today?

Vincey

Private Member

Would be good for "Plasterers"God I hope so.

Render & set......that will sort the men from the boys. Perhaps that is the meaning of "what goes round, comes round"God I hope so.

CeeVee

Well-Known Member

Please please please please!Render & set......that will sort the men from the boys. Perhaps that is the meaning of "what goes round, comes round"

Get these 'tackers', 'dabbers' and 'skimmers' back on the dole and get the proper tradesmen back.

Bauwer

Well-Known Member

Thanks for the detailed response. I think the only thing I'd add is that no provision is made in the target U values for a permeable wall or insulation layer.

By this I mean that if the insulation is breathable, and the wall is damp then the insulation properties of the wall and it's coverings are massively reduced. Any moisture in them will form a very efficient cold bridge over the whole area affected by the moisture.

> if the permeable wall of older building is damp and insulation is breathable, damp should dry out to outside as pressure is higher inside the building (as well as temperature) vs outside

> water can not pass inside to the Bauwer Light layer as it is protected by breathable Finish layer

The best solution in those instances is an impermeable inner layer (insulated board etc) separated from the mass of the wall by a vented cavity.

> please see Historic England recommendation below

If a material such as rockwool is used in contact with a damp wall it will not provide satisfactory according to the requirements of either the customer or the regulations.

> I agree, wet mineral wool do not perform

All of which clearly illustrates that there is no single solution to insulating an old building, and also that the building regulation requirements are flawed and sometimes contradictory when it comes to older buildings.

> Bauwer insulation is a effective and cost efficient solution for older buildings insulation in my humble opinion

I strongly disagree that introduction of impermeable inner layer (insulated board) is an acceptable solution for permeable older building, even with introduction of a cavity. The logic behind is described in every detail in the Historic England guideline for solid walls insulation of older permeable buildings (pages 5 & 9):

https://content.historicengland.org...sulating-solid-walls/heag081-solid-walls.pdf/

Impermeable insulation traps moisture within the wall and lead to damp and decay. Installed on the inside, it may do less damage to the building fabric itself, but will negate its ability to buffer moisture levels in the internal air. This can significantly reduce comfort for people using the building, who tend to try to compensate by turning the heating u. If the walls are already damp before installing insulation these effects would be potentially exacerbated with impermeable solution. Under these circumstances it is particularly important to allow walls to ‘breathe’ in order to dry to the outside as effectively as possible. Drying to the inside (external impermeable insulation option) is significantly less effective, and may be unpleasant for users of the building.

In summary it is critical not to mix modern (Celotex, EPS, PUR, PIR) and traditional insulation (Bauwer, Hemp-lime composites, etc) methods.

I also inserted my comments in the text above.

Last edited:

Bauwer

Well-Known Member

No ear biting or fighting, just a good technical debate.

There's a lot more to construction than is apparent at first glance, and it's always good to get things discussed as we can all learn from it.

Absolutely.

I asked one question to many architects at the recent Built Show exhibition at NEC Birmingham.

The question was

"What options are available to me in terms of insulating a 150 years old cottage with solid stone walls?"

Believe me or not, about 30% of architects advised me impermeable insulation solution.

When I asked further questions like what would happen when warmer moist air would heat a colder wall (internal impermeable insulation board scenario) they were not sure....another question was how the permeable wall would be passing vapour to the outside if it is blocked by impermeable insulation externally...drying inside is not that conformable for the people who live in the cottage..

We also just spoke to customer whose daughter bought a cottage. Few months after they found damp areas and further investigation revealed insulated plasterboard....now insulated plasterboard being removed and it will be replaced with a proper permeable solution.

zolco

Private Member

PIV units could be a solution to this, when you recover heat and circulate the air at the same time.Absolutely.

I asked one question to many architects at the recent Built Show exhibition at NEC Birmingham.

The question was

"What options are available to me in terms of insulating a 150 years old cottage with solid stone walls?"

Believe me or not, about 30% of architects advised me impermeable insulation solution.

When I asked further questions like what would happen when warmer moist air would heat a colder wall (internal impermeable insulation board scenario) they were not sure....another question was how the permeable wall would be passing vapour to the outside if it is blocked by impermeable insulation externally...drying inside is not that conformable for the people who live in the cottage..

We also just spoke to customer whose daughter bought a cottage. Few months after they found damp areas and further investigation revealed insulated plasterboard....now insulated plasterboard being removed and it will be replaced with a proper permeable solution.

Sent from my Nexus 6P using Tapatalk

Bauwer

Well-Known Member

Seems to me that in this instance though, while there are many solutions, all of them have some sort of drawback...

Sure, the opportunity might be to chose the right material in the right application area.

For example using Bauwer Light for a modern building insulation would not be the most efficient use of the material. Yet using modern, but impermeable insulation solution like Celotex, Kingspan, EPS, etc in the older permeable building could end up being a nightmare. I'd suggest each application area requires a specific solution, which is never "one fits all" silver bullet.

Dr.B

Active Member

It's been 2 yrs since I have done a float and set job.Please please please please!

Get these 'tackers', 'dabbers' and 'skimmers' back on the dole and get the proper tradesmen back.

Bauwer

Well-Known Member

Absolutely, they are all compromises.

Trying to make an old building work as it should with modern heating systems, wall finishes, insulation and the amount of internal moisture generated is never going to be completely successful. The closer to getting it to work you get the more expensive it is until you reach a point where the most economically viable solution is to flatten it and start again.

In my view there are two ways of approaching building insulation: modern and traditional. Modern method would keep the humidity out by vapour barriers, impermeable insulation and relaying on mechanical ventilation, moisture extraction system. This approach is used in the most of the new built houses.

Older, permeable solid wall buildings, cottages require traditional approach with permeable insulation solutions.

Lots of confusion comes from the expectation for older buildings with solid walls to achieve U value of 0.3

Clearly solid walls are less advanced vs wall with a cavity, while cavity wall insulation is expected to achieve only 0.55

The devil is always in the details and generally U value of 0.7 is sufficient for solid wall insulation and represents about 3 times improvement vs as built original U value.

There are number of houses were successfully insulated or repaired with Bauwer material; clearly flattening them would not be a reasonable option to consider.

Also U value targets need to be reasonable as well, eg. 0.7 for older solid wall, 0.55 for cavity insulation and 0.3 for the more modern buildings insulation where as built U value is better than 0.7 Those targets are reflected in the current building regs.

Danny

-

It's been 2 yrs since I have done a float and set job.

Its a shame really to be honest

D

Deleted member 23452

Guest

I strongly disagree that introduction of impermeable inner layer (insulated board) is an acceptable solution for permeable older building, even with introduction of a cavity. The logic behind is described in every detail in the Historic England guideline for solid walls insulation of older permeable buildings (pages 5 & 9):

https://content.historicengland.org...sulating-solid-walls/heag081-solid-walls.pdf/

Impermeable insulation traps moisture within the wall and lead to damp and decay. Installed on the inside, it may do less damage to the building fabric itself, but will negate its ability to buffer moisture levels in the internal air. This can significantly reduce comfort for people using the building, who tend to try to compensate by turning the heating u. If the walls are already damp before installing insulation these effects would be potentially exacerbated with impermeable solution. Under these circumstances it is particularly important to allow walls to ‘breathe’ in order to dry to the outside as effectively as possible. Drying to the inside (external impermeable insulation option) is significantly less effective, and may be unpleasant for users of the building.

In summary it is critical not to mix modern (Celotex, EPS, PUR, PIR) and traditional insulation (Bauwer, Hemp-lime composites, etc) methods.

I also inserted my comments in the text above.

I'm sorry, but some of your assertions are wrong.

Firstly there is no need to 'buffer moisture levels in the internal air'. It is as we all agree essential to allow a solid wall to breathe, which can be achieved either into the room itself, or into a cavity. That preserves the moisture flow through the wall structure, but prevents significant heat loss which is quite basic physics when you think about it. If that wasn't the case then cavity wall construction wouldn't work. It allows the outer skin to breathe and the cavity to dry to the outside.

Moisture levels inside the inner box formed by the insulation are balanced across extraction in the areas of highest moisture concentration, opening and closing doors, people exhaling, 'dry' heating systems, weep vents etc. Interstitial condensation isn't an issue as the cavity is vented which allows exchange of air yet still maintains drying to the outside. However, the drying effect is at a more constant rate as there is a much reduced temperature range of peaks and troughs because the inner face of the wall isn't exposed to the heating and cooling cycles caused by the houses heating systems.

So whilst I agree that an impermeable layer in contact with, or forming part of, the outer wall would be a bad approach, forming a vented internal cavity would most definitely not. As mentioned above, if it were then every building of cavity wall construction wouldn't work.